Chemical Film

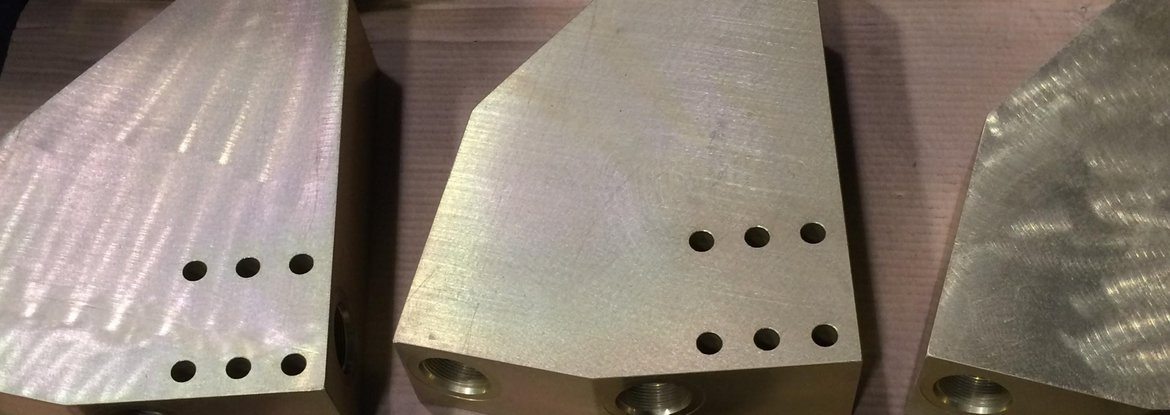

Chemical film is a protective coating that overcomes the poor adhesive qualities of aluminum and aluminum alloys. This undercoat provides protection and bonding capabilities to your substrate.

K&L Plating provides chemical film coating that adds an exceptional adhesion base for aluminum and alloys. That way, you can reliably add an organic coating to your aluminum or alloy application, or use it as a standalone coating.

The K&L Plating Advantage

No matter the size of the order, K&L Plating produces reliable outcomes on every order, as all our films and coatings meet rigorous military and ASTM specifications.

Nothing leaves our door before undergoing rigorous testing.

On-site Laboratory Testing

All of our quality assurance (QA) testing is done in-house in our qualified laboratory, conforming to ASTM and MIL-SPEC standards. This internal QA assures that you receive quality, consistent work from us every time. We’ll work quickly to deliver your job on schedule or earlier, and offer same-day quotes and expedited turnaround if you need it.

Benefits of Working With Us:

- Chemical film application that meets your exact specifications

- Meets MIL-DTL-5541F Types I & II specs (Class 1A & 3)

- Rigorous internal QA that meets ASTM and MIL-SPEC standards

- Fast quote and turnaround

Get a Quote for Chem Film

- Same day or next day quote

- Convenient pick up and delivery

- Expedited service available

Why Choose Chemical Film?

Our chemical film, applied through a chromate chemical conversion, adds a corrosion-resistant protective undercoating to aluminum and alloys. This film does not change the dimensions of the substrate, enabling you to remain within your tight tolerances. It allows you to paint or coat aluminum reliably, and in certain applications, can remain conductive to electricity.

Common Film Applications

- Aerospace: aluminum aircraft components

- Defense/Military: base coat for CARC paint for tactical equipment, ordinance, & vehicles

- Electronics: housing for electronic components

- Maritime: protection from saltwater corrosion

The Chemical Film Process

Our chemical film, also known by the trade names Alodine and Iridite, utilizes a chrome-based chemical reaction to protect aluminum and alloys. We can use both trivalent and hexavalent chromates, depending on specifications and your desired outcome. Through this process, we are able to provide two levels of coatings in either gold or clear. Class 1A provides a thick coating for maximum protection, and is best used bare or as a primer for paint or powder coating. The thinner Class 3 coating is best suited for electrical applications in which you want to retain electrical conductivity.

RoHS-Compliant

All of our plating and coating processes can conform to RoHS standards for environmentally-safer chemicals. If your application requires RoHS or any additional compliance standards in your industry, let us know and we can adjust our process to meet your needs.

Chemical Film works on

- Aluminum

- Aluminum alloy

Benefits

- Increased adhesion

- Undercoat protection

- Primer for organic coating

- Retain electrical conductivity (Class 3 coating)

Specifications

- MIL-DTL-5541F Type I (Class 1A)

- MIL-DTL-5541F Type I (Class 3)

- MIL-DTL-5541F Type II (Class 1A)

- MIL-DTL-5541F Type II (Class 3)

Plating Processes

We’re a full-service plating company and our work conforms to ISO standards. Plating services include:

- Anodize

- Blasting

- Phosphating

- Passivate

- Zinc plating

- Baking

- Electroless nickel

- Chemical films

- Solid Film Lubrication